Overview of the PUB’s requirements for grease traps

General Requirements

- Installation: Mandatory for all food establishments to control oil and grease to ≤100mg/litre. Exceptions for non-cooking establishments with PUB’s permission.

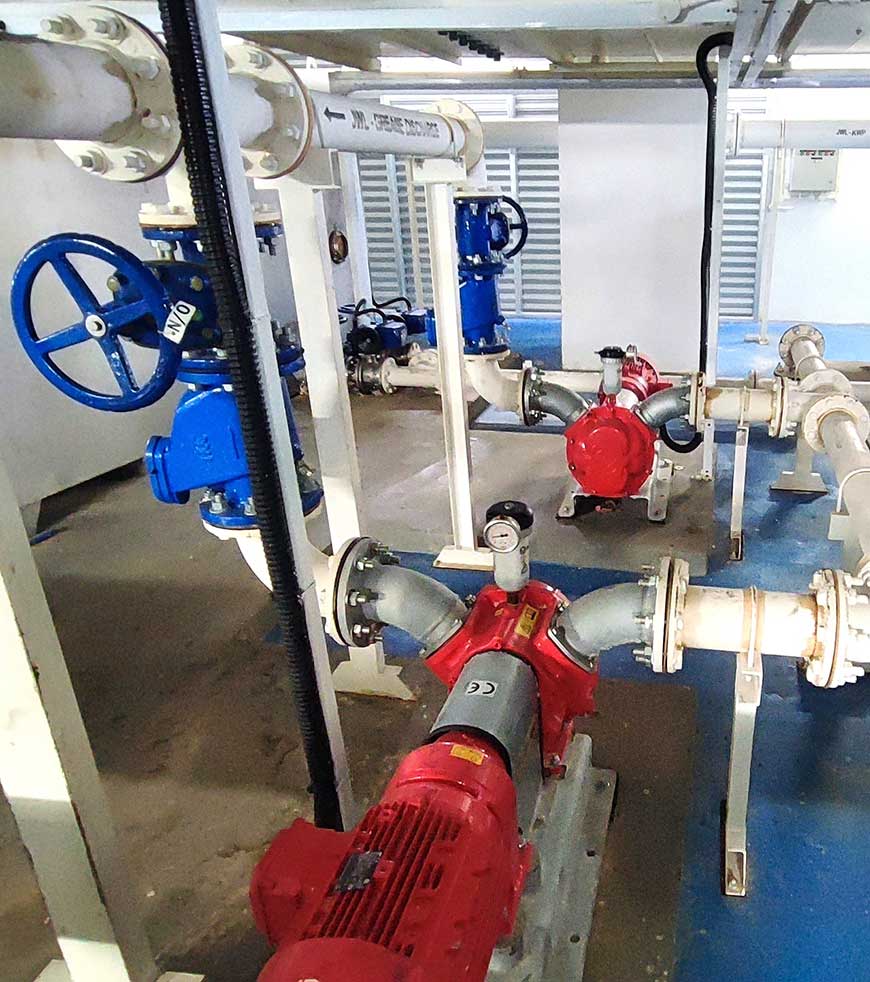

- Discharge System: Greasy discharge must be conveyed separately to grease traps.

Types of Grease Traps

- Standard Circular Grease Traps: Must comply with PUB’s Standard Drawings.

- Non-standard and Portable Grease Traps: Must comply with BS-EN1825 or ASME A112.14.3.

Sizing of Grease Traps

- Nominal Size: Based on BS-EN1825.

- Flow Rate Calculation: Based on appliances/fittings and typical flow rates from EN 1825-2, Table A.1.

Location and Accessibility

- Must be accessible for servicing and maintenance, and not cause nuisances or safety hazards.

Special Installations for Food Establishments

- Floor Wastes/Floor Traps/Waste Sumps: Required for sullage water discharge.

- Discharge Pipe Size: Minimum 100mm in diameter.

Minimum Size of Kitchen Discharge Stack

- Ground Level: Minimum 250mm in diameter.

- Above Ground Level: Minimum 250mm in diameter.

Portable Grease Traps

- Compliance Standards: Must comply with BS-EN1825 or ASME A112.14.3.

- Sizing Method: Based on nominal size and flow rates from EN 1825-2, Table A.1.

- Accessibility: Must be accessible for servicing and maintenance, without causing nuisances or safety hazards.

These guidelines ensure effective management of greasy discharge and compliance with regulatory standards.

How Greasera’s Products Fulfill These Requirements

Greasera grease separators are meticulously engineered to meet EN 1825 standards and tailored to adhere to the Singapore PUB Code of Practice to meet wastewater discharge regulations. Utilizing the Greasera Designer App, these separators can be precisely optimized to accommodate unique site constraints and the specific flow requirements of major food establishments.

Case Studies

Sizing And Design

Information On Sizing And

Designing Grease Separators

- Sizing and Dimensioning Based on EN 1825-2

- Ensures compliance with standards for grease separators approved by PUB Sin

- Accurate sizing for optimal performance.

- Appliances

- Considers various kitchen appliances that contribute to grease production.

- Helps in determining the appropriate separator size based on appliance usage.

- Number of Meals

- Calculates grease separator requirements based on the number of meals served.

- Tailors the design to the specific needs of the establishment.

- Type of Food Processing Plants

- Customizes grease separator solutions for different types of food processing plants.

- Addresses unique grease management challenges in various settings.

- Sludge Pumps Sizing

- Provides sizing for sludge pumps to handle grease and sludge efficiently.

- Ensures compatibility with grease separators for seamless operation.

- Immersive AR Visualization

- Offers real-time augmented reality (AR) simulation.

- Allows users to visualize the grease separator in their kitchen or plant environment.

- Design Data Generation

- Generates comprehensive design data for grease separators.

- Facilitates easy implementation and maintenance.

Our Commitment To Sustainability And The Environment

Greasera is deeply committed to sustainability, focusing on several key areas to minimize environmental impact and promote eco-friendly practices:

- Waste Reduction and Recycling: Greasera grease separators are designed to efficiently capture and recycle fats, oils, and grease (FOG) from kitchen wastewater. This prevents these substances from entering the sewage system and causing blockages or pollution.

- Energy Efficiency: Their systems are engineered to operate with high energy efficiency, reducing the overall carbon footprint of commercial kitchens.

- Sustainable Materials: Greasera uses stainless steel which prioritizes the use of sustainable and recyclable materials in their product manufacturing processes.

- Innovative Technology: They continuously invest in research and development to improve the efficiency and effectiveness of their products, ensuring they meet the highest environmental standards.

- Partnerships and Collaborations: Greasera collaborates with other organizations and stakeholders to promote sustainable practices and innovations in waste management and water treatment.

- Education and Advocacy: They actively engage in educating their customers and the broader community about the importance of sustainable waste management practices. These efforts collectively contribute to a more sustainable and environmentally friendly approach to managing kitchen wastewater.

Materials And Production

Materials Used in Our Products: Stainless Steel

Corrosion Resistance

Stainless steel is highly resistant to corrosion, which is crucial for grease separators that handle wastewater with varying pH levels. This resistance ensures a longer lifespan compared to materials like cast iron, concrete and plastic material.

Durability

Stainless steel can withstand high temperatures and mechanical stress, making it suitable for environments where the grease separator might be exposed to harsh conditions.

Hygiene

Stainless steel surfaces are easy to clean and maintain, which is essential for preventing bacterial growth and ensuring the separator remains sanitary.

Environmental Impact

Stainless steel is recyclable, which makes it an environmentally friendly option. Using stainless steel can contribute to sustainability goals in commercial and industrial settings.

Cost

While the initial cost of stainless steel grease separators might be higher than other materials, their long lifespan and low maintenance requirements can make them more cost-effective in the long run.

Associations

Industry Associations And Partnerships

Collaborative Projects And Initiatives

Got Questions?

We’re Always Here to Help.

If you have any questions or enquiries regarding our solutions, please do not hestitate to contact and we well get back to you shortly.